Industrial maintenance is the term for the process of keeping the equipment running at peak efficiency in a factory. It includes scheduled cleaning, parts replacement and lubrication, as well as repairs. The field of industrial maintenance does not involve just the repair of already existing malfunctions. Preventive maintenance typically is an important part of the field. As modern industrial machinery is expensive, it is usually important for businesses to ensure the upkeep of their investment. Preventive maintenance also may help ensure that machinery is safe, which can assist in maintaining the health of workers and equipment users.

Companies waste billions due to inefficient maintenance management. Projected onto the direct maintenance costs of 450 billion Euros in all European production plants, a savings potential arises of around 70 billion Euros a year. Alone in Germany 14 billion Euros are spent too much on maintenance every year.

Wireless Sensor Networks (WSNs) can be used to monitor different parameters related to industrial maintenance such as temperature, humidity, vibration and many other parameters. The monitoring of these parameters allows minimizing time and money as well as maximizing production.

Inblay System

Industrial motors are continuously

Fig. 1 – Project location

The solution

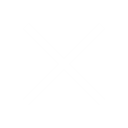

This project can be better explained with the following diagram:

Fig. 2.- Solution diagram

The 1st proof of concept of Inblay System consisted of 9 nodes measuring 2 different parameters:

- Temperature

- Vibration

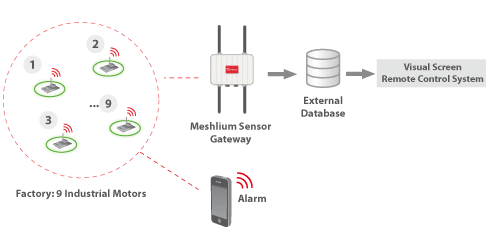

These sensors are connected to Waspmote through a special sensor board developed to integrate these two sensors. Temperature and vibration are key factors to industrial motors so these sensors needed to be very accurate. Thanks to the easy integration that Waspmote provides, this process took them just a few days.

Fig. 3.- Waspmote

Meshlium, Libelium’s multi-protocol router, is used to gather all the data from the sensor nodes and leave them in the Cloud. In this project, the nodes also sent an alarm message using the GPRS device when an abnormal vibration or temperature is detected.

In order to know where this sensor is located, each Waspmote can integrate a GPS, which delivers accurate position and time information.

Due to its low power consumption, Waspmote can be powered with batteries, solar panels or an external power source, making the nodes completely autonomous. Its power consumption can be seen below:

- 9mA – ON mode

- 62uA – Sleep mode

- 0.7uA – Hibernate mode

Waspmote is sleeping most of the time, in order to save battery. After some minutes (programmable by the user), Waspmote wakes up, reads from the sensors, implements the wireless communication and goes again to sleep mode.

Deployment process

Inblay was looking for a product which was accessible by the end-user through a visual screen. “The end-user wanted to know temperature and vibration on industrial motors in real-time, and this was a key factor to use Libelium´s products” says Antonio Perez, developer of Inblay System. Waspmotes were installed on the industrial motors and sent the data directly to a management sever, helping to establish a faster and more efficient service.

Waspmotes were able to provide Inblay with a friendly interface, but the end-user wanted to check that this platform was able to behave properly under real conditions. Real tests were carried out during several weeks in order to test the whole system. Thanks to the stability of the system, the end-user was totally satisfied and decided to install the system in its motors.

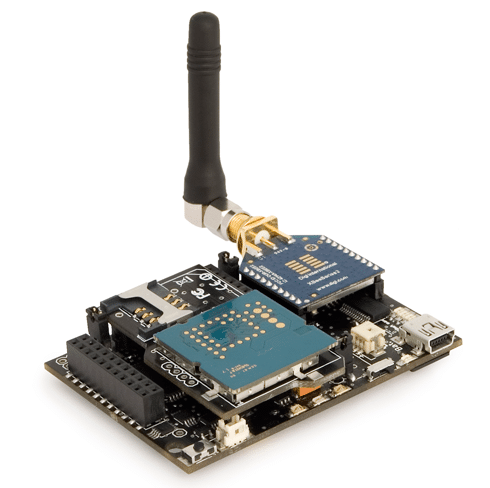

Figure 4 describes the installation in the motors and the visual screen that field workers see close to each industrial motor. In this way, workers can know the state of the motor in real-time.

Fig. 4.- Visual Screen on each industrial motor

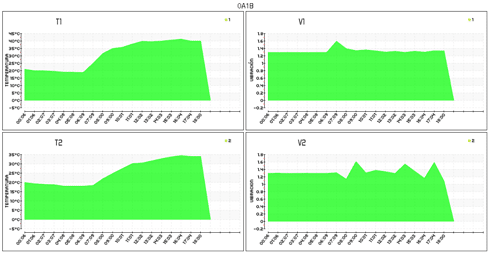

These data are also sent to a Meshlium which stores them into a MySQL database. Figure 5 shows a graphic representation of one industrial motor data, presenting temperature and vibration for that motor.

- This infrastructure (integration of Waspmote with

Inblay System) helpsmonitoring industrial motors in real-time to offer a better control for preventive maintenance. - Redundancy within the system guarantees a perfect performance.

- Quick and easy scalability allows facing peaks in production.

- High secured environment protects public data.

Friendly user interface provides field workers with a tool to ease maintenance.- Flexible infrastructure helps improving growing.

As a result of this project, industrial motors can be monitored in real-time to improve preventive maintenance.

Fig. 5.- Graphical representation of one industrial motor data

If you are interested in purchase information, please contact us.

References:

- Article from Libelium.com